Injection Moulding in an Anti-Plastic World

‘Plastic’ is a dirty word. With heightened environmental awareness, increasing regulations and pressure to reduce waste, the industry faces scrutiny like never before. At JC Moulding, this is seen as an opportunity, not a threat.

The philosophy is simple. Starting from part features all the way through to mouldability and material selection, the focus is on creating products that are fit for purpose and built to last. Circular design is not new, having end-of-life considerations central to the process is essential. True sustainability starts at the design stage, not as an afterthought.

Efficiency in manufacturing is a key principle bringing both environmental benefits and cost efficiencies. JC Moulding have recently installed their sixth closed-loop granulation cell, enabling zero waste for a large portion of part production. This investment demonstrates a commitment to reducing environmental impact while maintaining commercial viability. The purpose is to ensure sustainability and profitability work hand in hand, to the benefit of both customers and consumers.

In line with this, the business focuses on both productivity and environmental objectives. One area of improvement is on site conversion of any scrap that is generated to regrind. However, generating tonnes of reground material without any need or requirement, takes up valuable storage space. To be successful there is always the need to have part requirements in line with supply.

JC Moulding meet this challenge by testing the material and evaluating part performance on a case-by-case basis. On occasion, 100% reground material can be used, but JC Moulding is able to trial any mix to achieve the desired results. This reduces the need for virgin material, as well as closing the loop on the generated scrap.

“As the plastic industry strives to meet sustainability and productivity challenges, I believe the industry must lead with innovation and continuous improvement. We’re proud to be part of that movement, combining decades of injection moulding expertise with forward-thinking design and manufacturing. We like to think of ourselves as being the future of injection moulding.”

Chris Fall, Technical Director at JC Moulding.

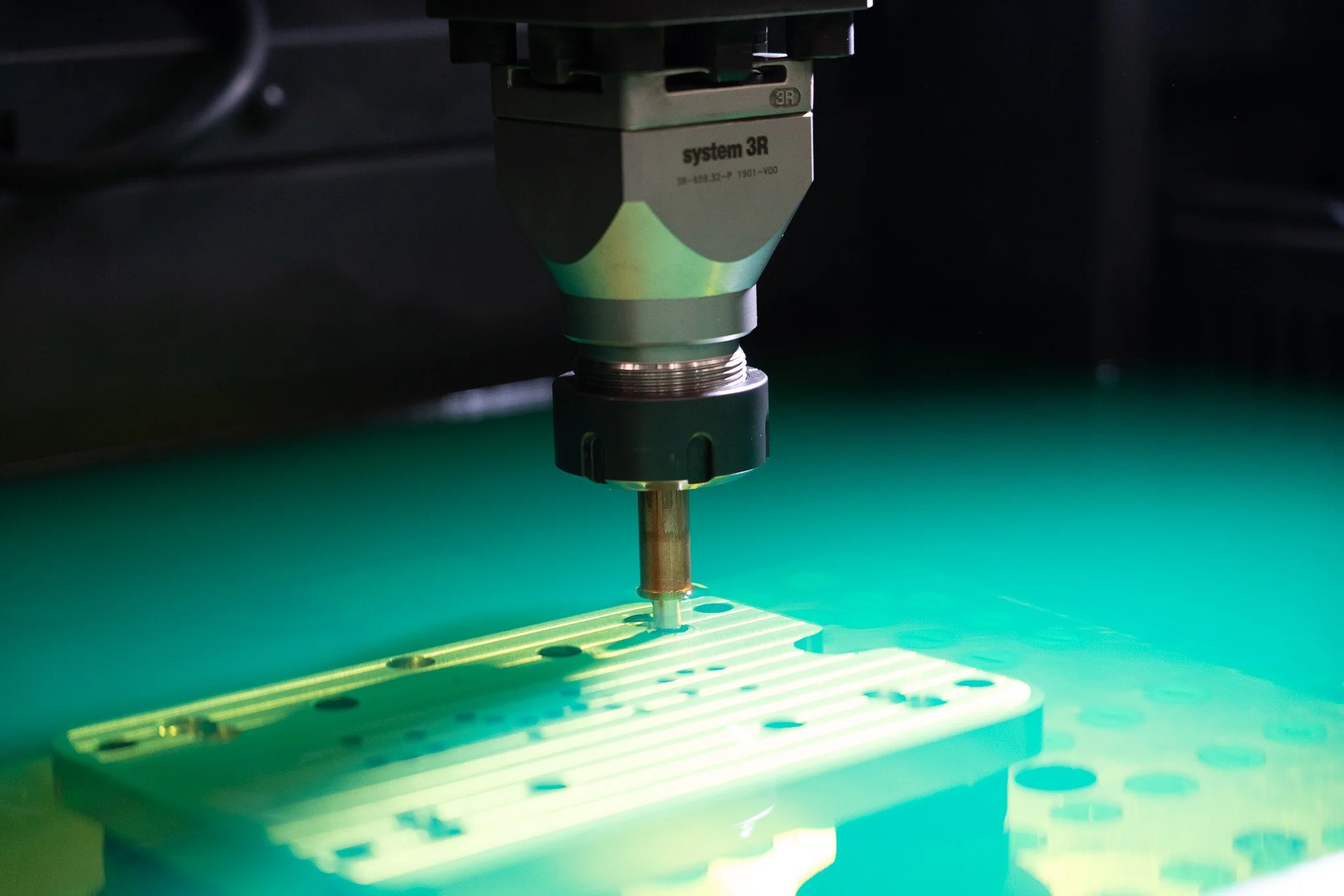

One of the key distinguishing features is the process. JC Moulding controls everything including part design, tool design, tool making, moulding, regrinding and assembly. This positions the company to achieve both sustainability and profitability while providing their customers with exceptional value and service.

JC Moulding

JC Moulding is a UK based provider of injection moulding services, whose unique method and expertise provides injection moulded parts without the high tooling costs of legacy practices.

Media Contact

Nick Williams

Senior Marketing Executive

sales@jcmoulding.com

01495315631

www.jcmoulding.com