Improving Business Efficiency Through Smart Technology Investment

The Challenge

For years, JC Moulding operated with a fleet of 25 second-hand injection moulding machines. While the company had built a reputation for reliability and quality over its 30+ years of operation, it faced growing challenges:

Increasing maintenance costs due to ageing, unreliable machines

Thousands spent annually on spare parts

Limited output capacity

Rising concern over long-term energy costs and environmental impact.

With a clear objective to minimize operational costs while maximizing productivity, JC Moulding knew it was time for a change. But after decades of using second-hand equipment, the idea of investing in brand new machinery marked a major shift for the company.

The Solution

JC Moulding set out to explore the potential benefits of upgrading to modern, energy-efficient machinery. After conducting a real-time energy usage test on their existing 90-ton clamp force machine, the findings were compelling:

By switching to a new Haitian Mars 90-ton machine, they could save approximately 75% of annual energy costs—equating to over £6,000 per machine per year.

Following a thorough due diligence process, including a site visit to Haitian’s German subsidiary, JC Moulding placed their first-ever order for a brand-new servo hydraulic Mars moulding machine.

The Results

The decision paid off—immediately.

With a monthly energy saving, the potential efficiency gains were so substantial, it made the commercial decision an easy one, we were able to see these gains from day one. The efficiency gains, lower maintenance needs, and increased reliability led to a full machinery replacement program across the business.

Energy Efficiency Comparison (real-life data):

Traditional Hydraulic

Cost/Unit: £0.13

Energy Usage: 22.6 kWh

Annual Energy Consumption: 58,478 kWh

Energy Saving/Year: –

Haitian Servo-Hydraulic

Cost/Unit: £0.13

Energy Usage: 4.3 kWh

Annual Energy Consumption: 11,126 kWh

Energy Saving/Year: 47,352 kWh (£6,155)

Looking Ahead

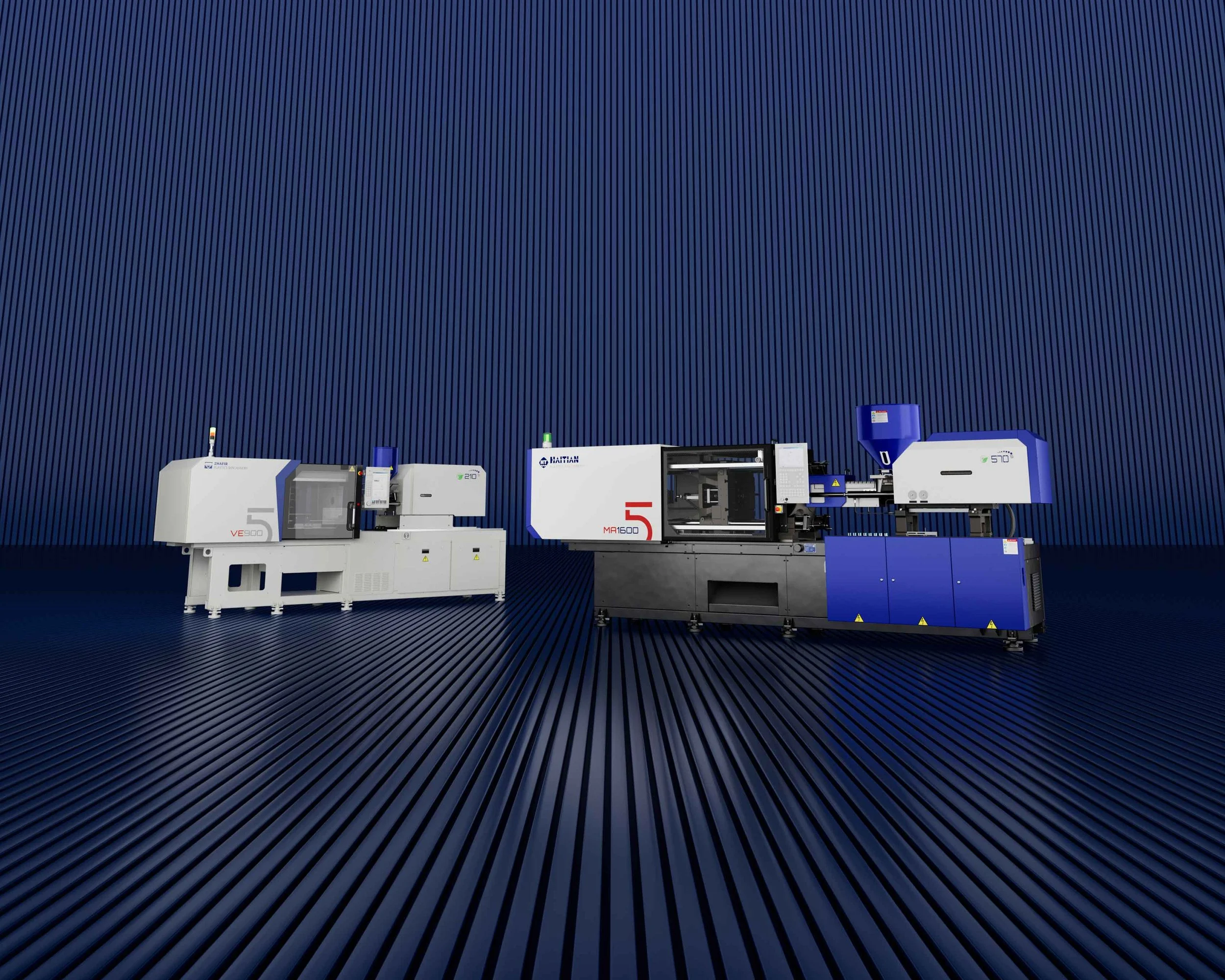

Thanks to the significant energy and cost savings achieved, plus the increased costs associated with soaring energy bills, JC Moulding has now replaced all their older machines with Brand new Haitian machines. Most recently, the company sold their first new Haitian machine after more than six years of productive use and is now reinvesting in Generation 5 Haitian machines—offering even greater energy-saving features and a 3 year warranty.

Their next step? Automation

JC Moulding is now investing in robot cells for every machine, aiming to further improve cost efficiency and production scalability.

Conclusion

By embracing new technology, JC Moulding not only improved its bottom line but also transformed the business for long-term sustainability and competitiveness. Their strategic investment in energy-efficient machinery has become a blueprint for modern manufacturing success as well as transforming their own business.